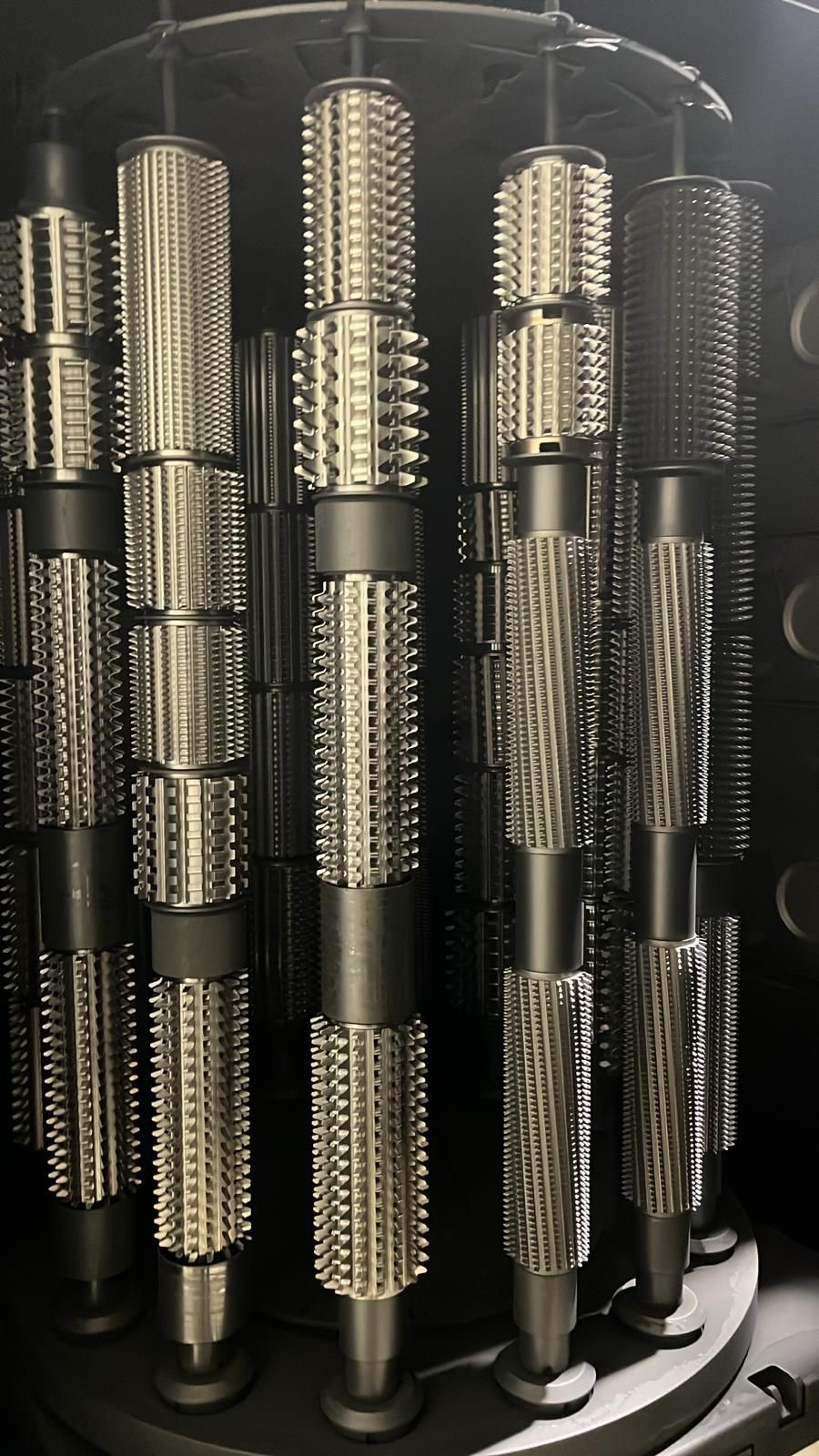

Our integrated coating center significantly increases the lifespan and performance of your tools: hobs, gear shaper cutters, shaving cutters, and round and flat broaches.

Equipped with Eifeler P900 and P400 furnaces, we apply high-performance coatings such as ALCRN, suitable for both high-speed steels and carbide.

Each coated tool is measured and 100% inspected: coating thickness, edge quality, deposit homogeneity.

Where the market tends to standardize on a single coating for all tool sizes, we make the opposite choice: find the right preparation and thickness to guarantee the best performance and longest service life for your tools.

The integration of coating into our global process allows us to reduce lead times and ensure consistent quality, in perfect continuity with our sharpening and re-profiling operations.